The artificial board industry is a green industry that is low-carbon, environmentally friendly, and sustainable. With abundant wood and bamboo resources, these materials can be given new value through the hands of the artificial board industry. They not only can sequester carbon dioxide in the air and achieve effective ‘carbon utilization’, but also can efficiently utilize forest residues, thereby saving social costs, reducing production energy consumption, and further enhancing carbon storage capacity.

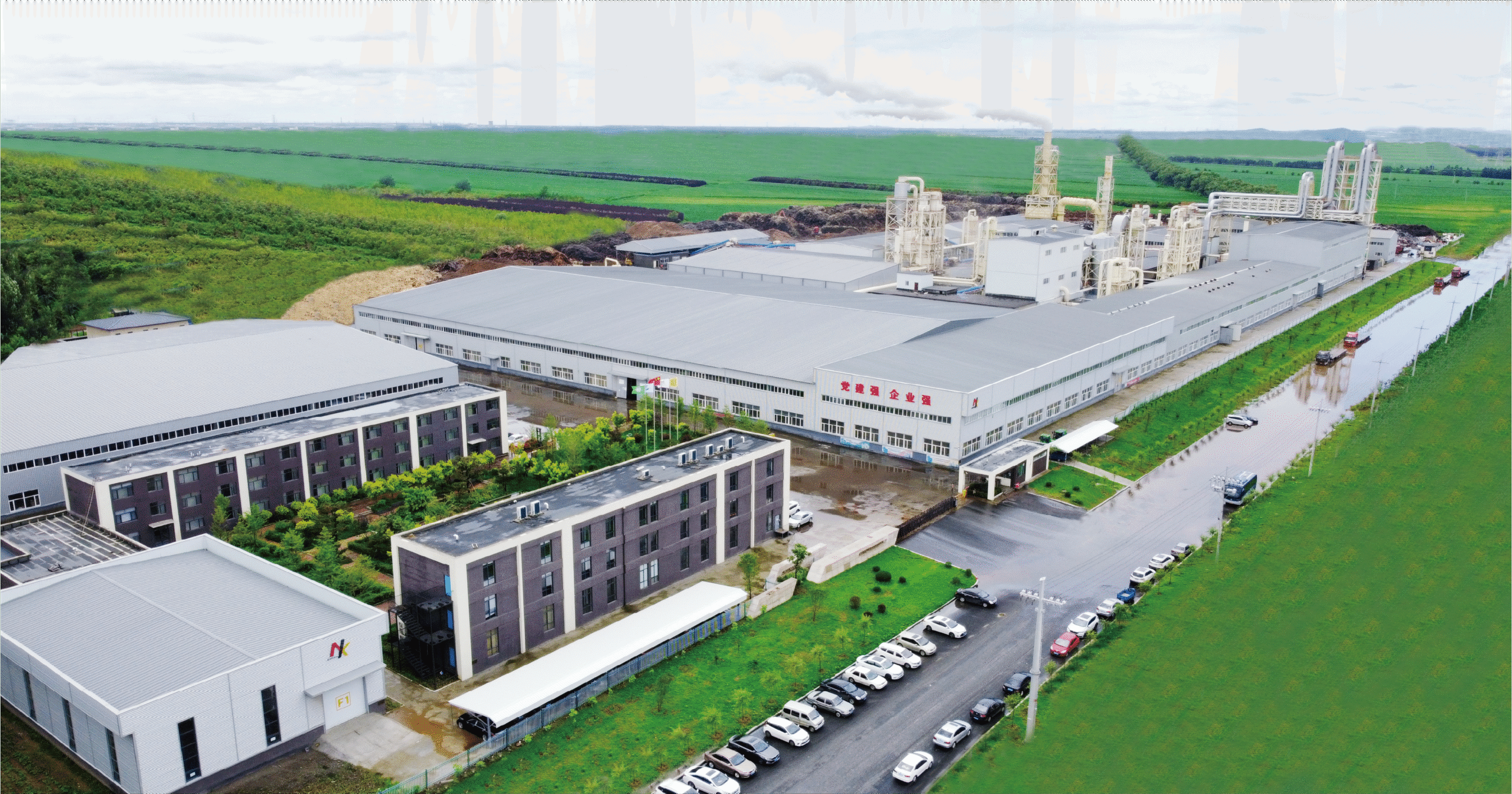

The NEARKUDOS Group has built a 5G+ smart factory to achieve automated and intelligent green production, green recycling, and low-carbon emissions, meeting international emission standards. It adopts advanced production equipment and processes from both domestic and foreign sources to achieve quality improvement and energy conservation in the production process, with a wood comprehensive utilization rate of up to 99.5%. It is also equipped with environmentally friendly MDI glue without formaldehyde, allowing the environmental quality of the products to be in line with international standards. The improvement of wood utilization rate is of great significance to the environmental cause. Only by maximizing the utilization of limited resources can we effectively address the severe imbalance between demand and supply.